Why Does Your Product Need Dry Granulation?

Comments Off on Why Does Your Product Need Dry Granulation?At Alexanderwerk, we partner with leaders across a range of industries, including pharmaceutical and chemical. Our expertise in dry granulation enables us to provide our customers with solutions for even the most complex powder handling processes. While we are headquartered in Germany, we efficiently serve our customers in Canada, the USA, and Mexico from our 17,000 square-foot facility in Pennsylvania. Offering extended services such as commissioning, calibration, training, and repair services, we consistently help our global customer base reap the many benefits of dry granulation.

The Process

To produce granules, there are two types of granulation processes: wet and dry. Wet granulation requires the addition of a liquid binder to form the granules, joining each individual particle together in a process known as agglomeration. Typically, wet granulation also necessitates a drying process to reduce the moisture within the granules. This can slow down the granulation process and may have a negative impact on the quality of the granules.

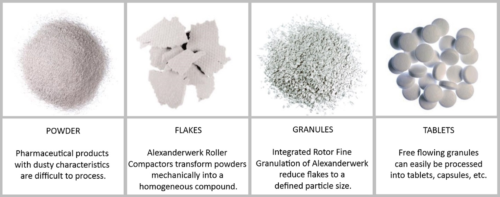

Dry granulation, on the other hand, does not require the manufacturer to add a liquid binder. This method utilizes a two-step process; first compacting and then milling the initial powder to create granules with the desired particle size distribution, and density. Most often, manufacturers will utilize roller compaction equipment, which functions by compressing the initial powder between two counter-rotating rollers.

While dry granulation is advantageous across an array of industries, there are some sectors that rely on it particularly heavily. These include:

- The chemical industry

- The pharmaceutical industry

- The food and beverage industry

When or Why Is Dry Granulation Required?

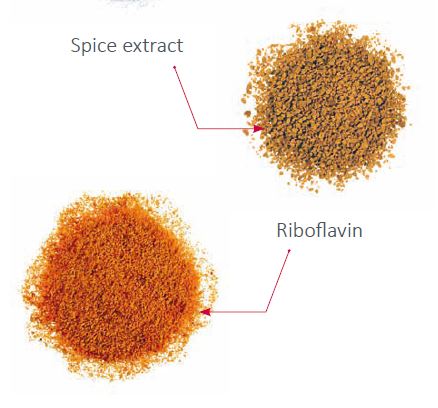

Due to the fact that it does not require a liquid binding agent, dry granulation is highly beneficial for applications that utilize active pharmaceutical ingredients (APIs). This is because the addition of liquid and a heated drying process may reduce the efficacy of certain APIs. Furthermore, there are many products in the food and chemical industries that are also very heat sensitive. There are two types of material in particular that require the dry granulation process.

Moisture Sensitive Materials

Certain bulk materials, e.g APIs in the pharma industry, react negatively when they come in contact with moisture. This means that the API is at risk of losing vital chemical properties, thus rendering it ineffective. As these types of materials will not function after undergoing wet granulation, manufacturers must opt for dry granulation instead.

Temperature Sensitive Materials

Once a material has undergone the first step of the wet granulation process, the manufacturer must then put the material through a drying process. Even if a material can handle exposure to moisture, it must also be able to withstand high temperatures if it is to maintain its efficacy after it is dried. If the API in question is sensitive to temperatures, dry granulation is required.

Overall, regardless of the initial properties of the powder blend, the goal of dry granulation is to increase both the particle size and the bulk density of the powder. Both of these outcomes serve to improve the flow of distributed material, thus increasing the efficiency of the manufacturing process.

However, increased efficiency is just one of the advantages of dry granulation. A manufacturer or pharma CDMO may opt for dry granulation due to the fact that dry granulation machinery is smaller and requires minimal amounts of floor space. This process is also very flexible, as it functions well for both large and small volume runs. Additionally, dry granulation is significantly less likely to result in any type of alteration in drug morphology when compared to wet granulation.

Other advantages of dry granulation may include:

- Improved blending and a fixed blend uniformity

- Improved tablet disintegration time

- Dense compaction

- Reduced friability

- Dust reduction

- Reduction of material volume during handling and storage

Partner With Alexanderwerk for Your Dry Granulation Needs

Dry granulation is an efficient and reliable process with a variety of advantages. At Alexanderwerk, our specialists are well-versed in this process, and we work closely with our customers to find the appropriate solution and ensure optimal results for each unique application. Learn more about our dry granulation equipment, or contact us to discuss your project and schedule a consultation.

Let’s talk and collaborate with us helping solve your most difficult granulation challenges.

WP120 and WP200 Pharma in Alexanderwerk Inc’s Chem Lab

WP120 Pharma in Alexanderwerk Inc’s Pharma Lab